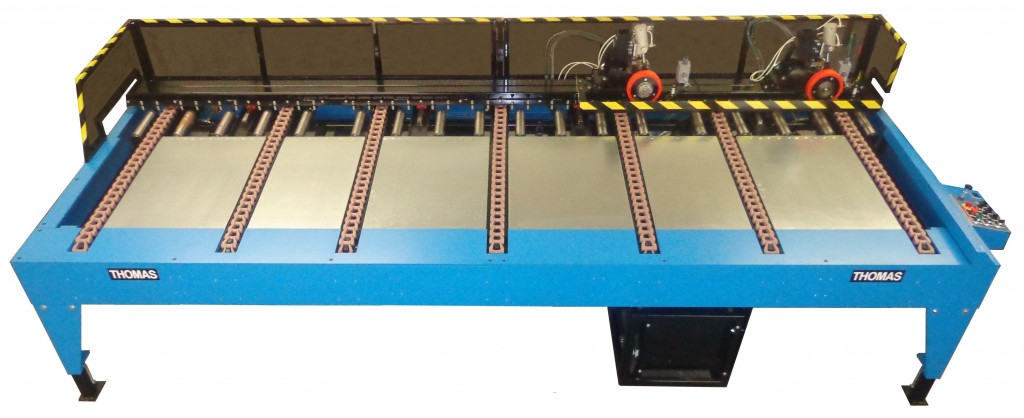

Lateral Feeders

- Efficiency Maximized with continuous lateral butt-feeding

- Cool and Quiet Operation with a pressure-compensating hydraulic system

- Quick Ratio Changes with independently adjustable speeds of lateral chain and feed drive rollers

- Chain Life Improved due to elevation of parts from four idler rollers

- Fast SetUp because bridge guides are quickly adjustable

- Quick Height SetUp Changes with adjustment cranks

- Durable and Quiet UHMW lateral feed chains

- Heavy-Duty Integrated steel frame moulder feeder

- UHMW feed chains move parts laterally to polyurethane feed rollers.

- A photo eye detects a part which causes feed rollers to lower onto part propelling — butt-feeding — it into moulder.

- At the trailing end of the part, the feed rollers raise to allow the next part in. The cycle is repeated.

- Stand-Alone Bridge Feeder

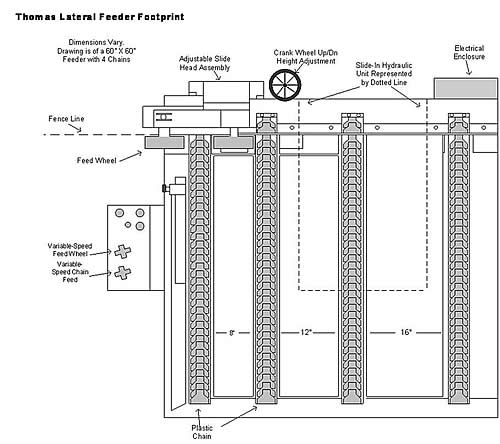

Machine Specifications

- Table lengths available: 60″, 72″, 96″, 144″, 168″

- Number of Chains: 4, 5, 6, 7, 8, 9

- Table widths available: 30″, 36″, 48″, 60″, 96″

- Height (adjustable): 30″ to 38″

- Power: 3-Phase, 230 / 460 Volt

- Motors: Variable hydraulic

- Length: 16″ Minimum

- Width: 1″ Minimum

- Thickness: 0.25″ to 3″

- Tilt feeding

- Customized material dimensions

- Locking Casters

- Six wheel bridge feeder