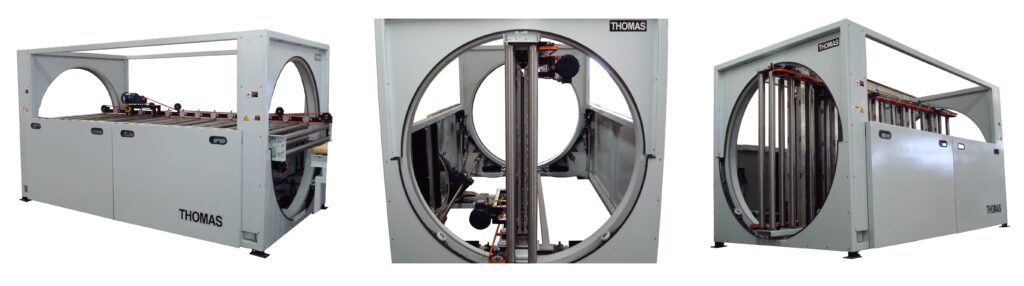

Barrel Turner

- 10-12 Second Cycle Time

- Servo Motor Driven Barrel Flip

- (8) Variable-Speed 24vdc Rollers Stepped Speed Matching

- 2 1/2" Sleeved 11/16" Hex Shaft Pop-In Idler Rollers

- Controls on Enclosure or Optional Remote with Pedestal

- Pneumatic Clamps with Safety Interlocks to Safely Secure Parts

- Heavy Duty Steel Frame with Adjustable Jack Legs

- Custom Sizes Available Upon Request

- Used for Doors, Windows, Wood Panels, and Laminate Panels

- Servo controlled action

- 10 second or less cycle time

- PVC Sleeved Rollers

- Pneumatic center clamping, aluminum framed, padded clamp bars

- Smooth and Quiet Timing belt drive

- Full frame shielding.

- Heavy Duty square tubing frame with adjustable legs

- Minimum pathline related directly to max product width

- Infeed and Outfeed Product sensors

- Urethane Sleeved Rollers

- Allen Bradley Controls Upgrade

- Serpentine Daisy Belt Powered Roller Upgrade

- Infeed Sensor detects leading edge and then trailing edge of product.

- PLC stops roller feed for pneumatic center padded clamp arms to lift and clamp product.

- Bed servo drive turns bed 180 degrees and plc reopens center clamping arms.

- Product exits either the rear or front of the machine depending on process till trailing edge or downstream signal resets cycle.

208/ 230 / 240 Volts

- 3 Phase

- 60 Hertz

- 6 Amps

440 / 460 / 480 Volts

- 3 Phase

- 60 Hertz

- 10 Amps