Wood

Reliable Solutions for Demanding Workshops

From material handling and panel processing to automated assembly and finishing systems, our equipment is built to withstand the daily demands of high-volume woodworking environments.

The Barrel Turner features two powered roller decks with 10” roller spacing. 24VDC variable speed powered rollers are proportionally mixed with non-powered rollers to infeed the product. After being received into the rotating bed, products are pneumatically center clamped with non-marring pads. Now securely held, products are flipped in 8–10 seconds. After rotation, the product can either pass through the system or return out the infeed. Available in powered roller and wide belt models, the unit accepts single panels and full charges, with custom sizing options available to fit your production needs.

" We use these Barrel Turners inline with some of our other equipment used to sand, finish, and trim the doors that we make. These Barrel Turners flip the doors as they go through the process to get both sides of the door" - Evan, Trustile Doors LLC

The Turnbak return conveyor is designed for edgebanders, using photo-eye technology to detect the trailing edge of each part. Once detected, the receiver rollers lower, allowing urethane belts to transfer the part to the return side. After the part exits, the rollers raise and the cycle repeats. Powered infeed arms are pneumatically clutched to match the edgebander’s speed, and rectangular parts are automatically turned. Built with a reliable Max Drive system, steel rollers with PVC sleeves, and variable-speed rollers up to 120 FPM, the machine offers smooth, efficient product return. The unit includes PLC control, a portable HMI remote, adjustable height, and is available in multiple horsepower configurations with optional features for heavy parts.

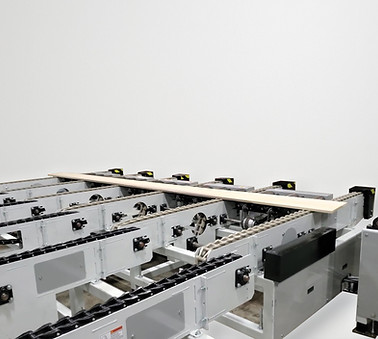

Transfer Conveyors are utilized for many operations to manipulate product positioning, direction of travel, and accumulation. Load capacity designs are derived from the customer’s specific needs. Steel, acetal, nylon chain or urethane belting can be used for transference with drive options of daisy chain drive, 24 vdc, and under the roller max drive polyurethane belt drive roller systems. These machines can be built with roller lift trays, stripper chains, accumulation decks, or integrated with overhead Pick-N-Place gantry systems.

Paybaks are an economical return conveyor designed for smaller operations or standardized small cabinet parts. Built from heavy-duty structural steel, it offers long-lasting durability and smooth part handling. A spring-loaded urethane hold-down ensures part transfer, while adjustable jack legs and infeed height allow compatibility with a wide range of machines. four-inch roller spacing and close belt placement enable the efficient return of small parts - down to 4" x 4"- without additional attachments. Powered infeed rollers, urethane transfer belts, and PVC-sleeved return side steel rollers deliver consistent performance, while the Max Drive roller system provides years of maintenance-free operation. The Paybak is relay logic controlled, features a portable variable-speed remote (0–120 FPM), and is available in multiple sizes to suit your specific application needs.

Our Air Tables are designed to support the smooth and efficient handling of products across a variety of industries, including textile, steel, wood, packaging, and paper. Featuring a machined phenolic top and acetal diffuser coins, these tables create a low-friction surface ideal for omni directional movement. Built on a durable 2" x 11 gauge laser cut steel frame, they offer long-lasting stability and performance. Standard models provide a 13–15 lb capacity lift per square foot, with higher lift capacities available. Customizable with options like scissor lifts, pneumatic lifts, hand crank lift, and lateral sliding tops. Air Tables can be tailored to meet your exact application needs. Available in multiple voltage configurations and built for seamless integration into your existing workflow.

The Sandbak return conveyor is designed for use with sanders, recirculation applications, and finishing lines offering smooth, automated part return to improve process efficiency. A photo-eye detects the trailing edge of each part, triggering the receiver infeed section to lower onto urethane transfer belts. These belts move the part laterally to the return side, after which the infeed section raises and resets for the next cycle. With four-inch roller spacing, the Sandbak can handle charges of parts down to nine inches in length. Built on a heavy-duty structural steel frame with adjustable jack legs, it features a reliable Max Drive system, variable-speed rollers (0–120 FPM), and an HMI remote for operator control. HDPE slides provide smooth belt transfer support. Custom sizing is available to fit any machine or part size, and the unit operates on standard 3-phase power with minimal air requirements.

We understand that no two shops are the same. That’s why we work closely with your team to create custom machinery solutions that solve your unique production challenges

Our Woodworking Industry Solutions Include:

-

Barrel Turner for inline product inversion.

-

Custom transfer conveyors for inline or 90 degree material transfers between process stations.

-

Paybak and Turnbak conveyors for ergonomic material return handling.

-

Sandbak conveyors for product recirculation.

-

Tailored integration with your existing product lines for optimized throughput and safety.

Have a similar challenge? Click here to talk about how we can streamline your workflow process!